Pneumatic and hydraulic damping systems contain pneumatic cylinders or hydraulic cylinders which employ a steel piston, a piston rod, a cylinder barrel setup to help deliver the damping effect. As compressed air or fluid moves into a pneumatic or hydraulic cylinders, it pushes the piston up or down through the length of the cylinder. The reflex action of the piston is either activated by either the compressed air or by a spring mechanism, which brings back the spring to its original position. These are also called Single Action Cylinders. Cylinders come in a variety of types and may either be pneumatic cylinders, electro pneumatic cylinder, hydraulic cylinders or electro hydraulic cylinders. Double Acting Cylinders (DAC) employ the force of air to move in two ways, in an extend stroke and a retract stroke. Double Acting Cylinders have two ports, one for outstroke and one for in-stroke.

As the industry requirements may vary, pneumatic and hydraulic cylinder come in a variety of bores and strokes configurations. These may vary between being smaller than an inch all the way up to several feet. The power of compressed air or air may range from a few pounds per square inch to hundreds of pounds creating enough power and force of a few thousands of pounds. The pistons rods are usually made of toughened alloy steel. Cylinder pipes are seamless drawn and are precisely honed to the smoothest finish to prevent corrosion and provide long life for piston-seals.

Valves present inside the pneumatic and cylinder help regulate the flow of compressed air or fluids and maintain the pressure inside the pressure inside the pneumatic or hydraulic cylinder. Some pneumatic cylinders reach 1000 mm in diameter, and are used in place of cylinders for special circumstances where leaking hydraulic oil could impose an extreme hazard. Pneumatic and hydraulic cylinders also find application in automated shutters in train and tram doors, and automated exits that are monitored and activated by sensors. The low friction nature of arrangement in Pneumatic and hydraulic cylinders enable a smooth, slow-speed operation and at a low pressure which is a safety consideration in human traffic areas.

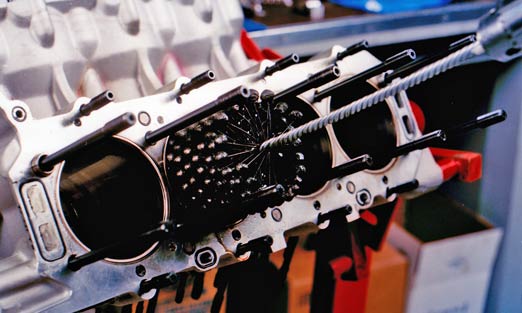

Metal for cylinder hone.