Heavy industrial and automotive machines work on the principle of

hydraulics. Hydraulic cylinders are an integral part of such machines.

They also play a major role in domestic applications like door stoppers

and elevators.

Hydraulic system function on one basic principle

-force applied at one point in the system is transmitted to another

destination with the help of incompressible lubrications, (say oil).

With a prolonged sudden force applied in the system, cylinders tend to

face wear and tear over a period of time. A crack in the system leads to

the issue of hydraulic cylinder repair, which can incur heavy cost. The

repairing can increase your expenses considerably and the overall

process is quite laborious too. However, exuberant loss can be neglected

if you use the right tools and guidelines to carry out the entire

process.

Hydraulic system function on one basic principle

-force applied at one point in the system is transmitted to another

destination with the help of incompressible lubrications, (say oil).

With a prolonged sudden force applied in the system, cylinders tend to

face wear and tear over a period of time. A crack in the system leads to

the issue of hydraulic cylinder repair, which can incur heavy cost. The

repairing can increase your expenses considerably and the overall

process is quite laborious too. However, exuberant loss can be neglected

if you use the right tools and guidelines to carry out the entire

process.

Use the Right Tools for Effective Repair

The main factor to take into account is ensuring you or your servicing company is using the appropriate stools. It is recommended to use tools that are strong, simple and durable.

Hydraulic Cylinder Repair and Maintenance

Hydraulic cylinder repair is the most cost effective methods for gaining high end productions. However, there are various methods to carry out the repairing process. Online approach is an ideal method to find suitable service companies to repair your instruments. Check for numerous websites, compare online quotations and testimonials posted on different websites, and you will certainly find good reference material, people's experience and organizations that offer service.

When the hydraulic cylinder repair kit is dispensed ensure the parts are lubricated well for proper functioning. If any issues pertaining to piston seal or rod, rod seal surfaces, check them thoroughly and replace it with authentic certified parts. It is advisable to follow this right approach for the repairing to go smoothly.

Hydraulic system function on one basic principle

-force applied at one point in the system is transmitted to another

destination with the help of incompressible lubrications, (say oil).

With a prolonged sudden force applied in the system, cylinders tend to

face wear and tear over a period of time. A crack in the system leads to

the issue of hydraulic cylinder repair, which can incur heavy cost. The

repairing can increase your expenses considerably and the overall

process is quite laborious too. However, exuberant loss can be neglected

if you use the right tools and guidelines to carry out the entire

process.

Hydraulic system function on one basic principle

-force applied at one point in the system is transmitted to another

destination with the help of incompressible lubrications, (say oil).

With a prolonged sudden force applied in the system, cylinders tend to

face wear and tear over a period of time. A crack in the system leads to

the issue of hydraulic cylinder repair, which can incur heavy cost. The

repairing can increase your expenses considerably and the overall

process is quite laborious too. However, exuberant loss can be neglected

if you use the right tools and guidelines to carry out the entire

process.Use the Right Tools for Effective Repair

The main factor to take into account is ensuring you or your servicing company is using the appropriate stools. It is recommended to use tools that are strong, simple and durable.

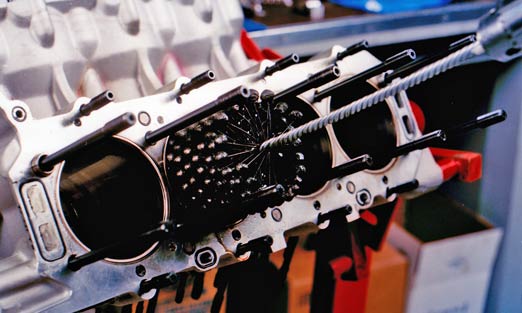

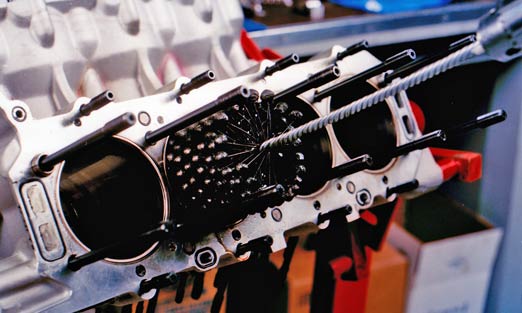

- Keep a Graphical Layout of the hydraulic cylinder assembly ready as reference before commencing the repair.

- Keep your repair kit ready for use. The kit consists of new shaft seals, O-shaped rings, a pressure boost system, a ratchet and a disassembly table that is used for assembling or disassembling the cylinders during rebuilding or repairing.

- Use of Ratchet is the right option in the rebuilding or repairing of hydraulic cylinders. Ratchets are used to install or remove cylinder heads and piston nuts in the system.

- Hones ensure thorough filtration, oil flow and containment during the repairing process. Lubrication is the most important aspect for any machine to function smoothly. Hence, it is necessary for the piston shaft to get the right type of lubrication and achieve the desired performance level.

Hydraulic Cylinder Repair and Maintenance

Hydraulic cylinder repair is the most cost effective methods for gaining high end productions. However, there are various methods to carry out the repairing process. Online approach is an ideal method to find suitable service companies to repair your instruments. Check for numerous websites, compare online quotations and testimonials posted on different websites, and you will certainly find good reference material, people's experience and organizations that offer service.

When the hydraulic cylinder repair kit is dispensed ensure the parts are lubricated well for proper functioning. If any issues pertaining to piston seal or rod, rod seal surfaces, check them thoroughly and replace it with authentic certified parts. It is advisable to follow this right approach for the repairing to go smoothly.

Being a professional Technical Engineer I am always writing

articles about the latest technology used in industrial usage has been

my forte over the last few years. Follow my write ups to know more about

the latest technologies use in mechanical industry. This fall Hydraulic

cylinder repairs, Gearboxes repair are very much in demand among the

heavy industry across the world. Keep yourself updated on these products

exclusively from USA.

I think that using hydraulics to clean engines really is an ingenuous way to make sure that everything is cleaned properly. What I really like about this post is that you mentioned to make sure that you're using the right hydraulic for your situation. I had no idea that using the right hydraulic was something that was such a big deal. http://www.tsthydraulics.com/

ReplyDelete